Sustainable

Production

System

System to consolidate

Sustainability in processes

of a production business

Take opportunities inherent in the transition to sustainability to improve results:

Economic - Social - Environmental

Factory Sustainable Transition

The transition to sustainability is now an unstoppable reality. Companies aim to seize the great opportunities inherent in this transition in Economic (productivity, efficiency and quality), Social (inclusion, safety) and Environmental (eco-sustainability) terms. The Paris Agreement signed in September 2015 confirmed its commitment by 2030, signed by over 150 international present Leaders, at the United Nations. The document was summarized and disseminated through the Sustainable Development Goals (SDGs) in 17 objectives:

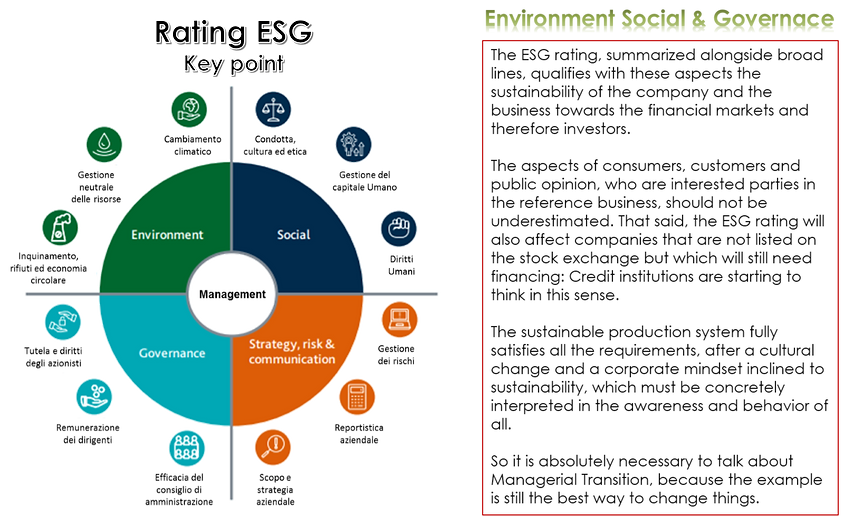

The simplistic synthesis can be summarized in the commitment to safeguard the environment, integrate and support the company and ensure ethical management in legal and economic terms. Up to now, governments have done very little, obviously also held back by the pandemic situation, but there are only 9 years left by 2030 and, very soon, they will have to convey all the interested parties to converge towards Economic, Social and Environmental sustainability. Finance, investors and all banking bodies have already implemented evaluation processes to facilitate the analysis through ESG parameters, which are now a fact.

So, from now on, companies will have access to credit by returning to the Sustainability standards and that is why we are increasingly talking about the transition to sustainability (Sustainability Transition).

What should a company do to move towards sustainability?

First of all, focus on the gap from the minimum rents in Environmental, Social and Economic terms.

As an example:

Are the environmental impacts (waste, CO2, emissions, raw material extraction) constantly decreasing compared to the previous year with the same production?

Are the staff perfectly integrated and gratified? Is the social impact of the product sustainable, that is, does it fall within the canons of the SDGs? Are there policies applied for equal opportunities in the company organization? Are meritocratic methods objectified? Is the corporate and / or social welfare consistent? Are social and local initiatives in place?

Does the company create wealth for itself, for investors and stakeholders? Is the value chain economically sustainable? Does corporate governance respect the highest ethical standards? Are there managers with disproportionate remuneration? Is the Board of Directors involved in the management of the Business?

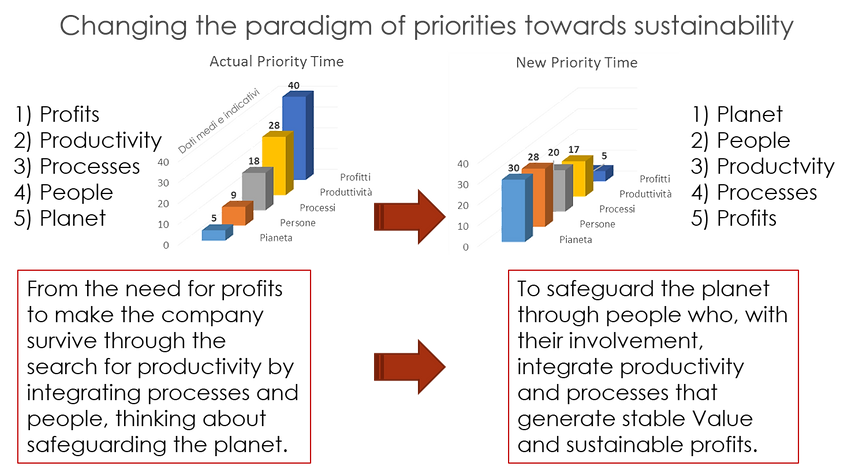

Obviously the quotes are by no means exhaustive and have the sole purpose of leading you in the order of ideas, which in part may already have been implemented. In the event that there were open points, we fully understand the need to redesign the paradigm of business priorities and how this is an essential point:

I find the 5P methodology very interesting.

Making profits a consequence with the support of all.

Having reviewed the priorities, we identify the 7 key points of the process towards sustainability:

In the diagram, Productivity is at the center, surrounded by Costs, Environment, Efficiency, People, Safety and Quality.

Does that tell you something? It's not a casuality!

I would just like to mention the definition of productivity:

Do the same things at a lower cost

Doing more things at the same cost

Doing more things at a lower cost

Therefore, we can say that productivity is not only a function of itself through investments and technical solutions, but it is also a consequence of the other points:

Eg:

- by reducing the production of waste, the disposal costs will be lower, the environmental impact will be less invasive and therefore we will do the same things at a lower cost. Another example: by reducing waste, it will lead to energy savings, therefore less emissions, less waste of raw materials, etc etc. Also, integrating People, guaranteeing safety and improving the efficiency of production plants.

Having clarified this aspect of sustainable thinking, we therefore need a method, or rather, a system to be able to link these key points and make them operational and feasible. At the moment there is no consolidated system that accompanies the company to the sustainable transition. This is my method for Sustainable Production System (Sustainable Production System):

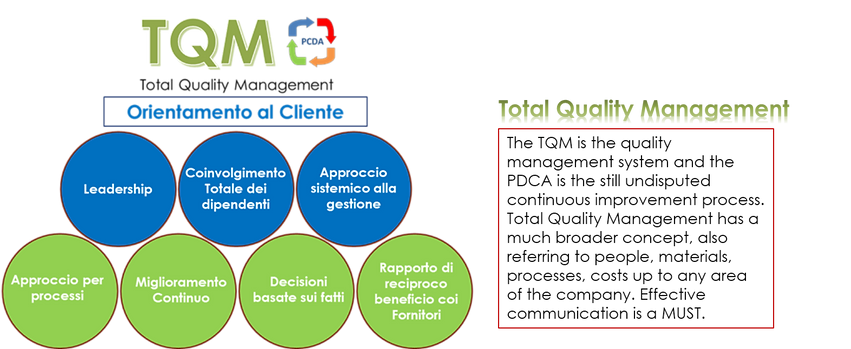

Total Quality Management is the same as always, developed in Japan, widespread in the 1950s and became the ISO standard, integrated with the Deming cycle . (Plan Do Check Act)

The much more recent R paradigm , coined in 2017 by Kirchherr, J., Reike, D., Hekkert, M., supercharges the 3R approach (Reduce - Recycle - Reuse)

It was made some minor corrections to the Temple Lean inserting the logic of Clear Cost Definition, Human Capital Development and the approach Safety First by japan that I think is among the most pragmatic.

As we can see from the diagram below, the integration of these three systems give greater prominence to the purpose, acting both for specificity and for contemporaneity on Productivity, Costs and People.

This strategic solution is currently the most pragmatic for complying with the sustainable transition.

It will be a pleasure to meet you, make a brief presentation of the Production System and show you the matrices of the intersections with the key points and evaluate the applicability and advantages for the company.

Contact me at +39 340 000 6101 or write me at: paolo.battista63@gmail.com